Take out any spinning rust and pack those in a foam HDD case. Number them as you pull them for easy reinstall.

Put a bit of plywood under the rack, ratchet strap it, and now you can put it on a dolly without the lip hitting the equipment as you try and lift it. For avoiding it falling off the dolly, use a 2nd ratchet strap and wrap it around the chassis / dolly.

Put a 2nd piece of plywood on top once its in the uhaul so you can load more boxes on top… Maybe even do that at first so the initial strap is securing it as well.

As for the bottom plywood, if you add some felt pads, then it will help you shimmy the chassis into / out of its position once its unloaded. I have my rack vhb taped to ply with felt under it and recommend it to people IRL a fair bit.

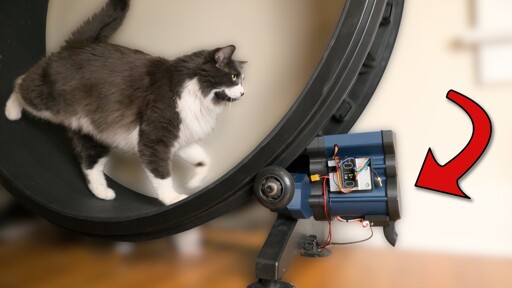

He does little bursts of running with periods of walking in between, so I dont think it would work. Perhaps with other cats it would though